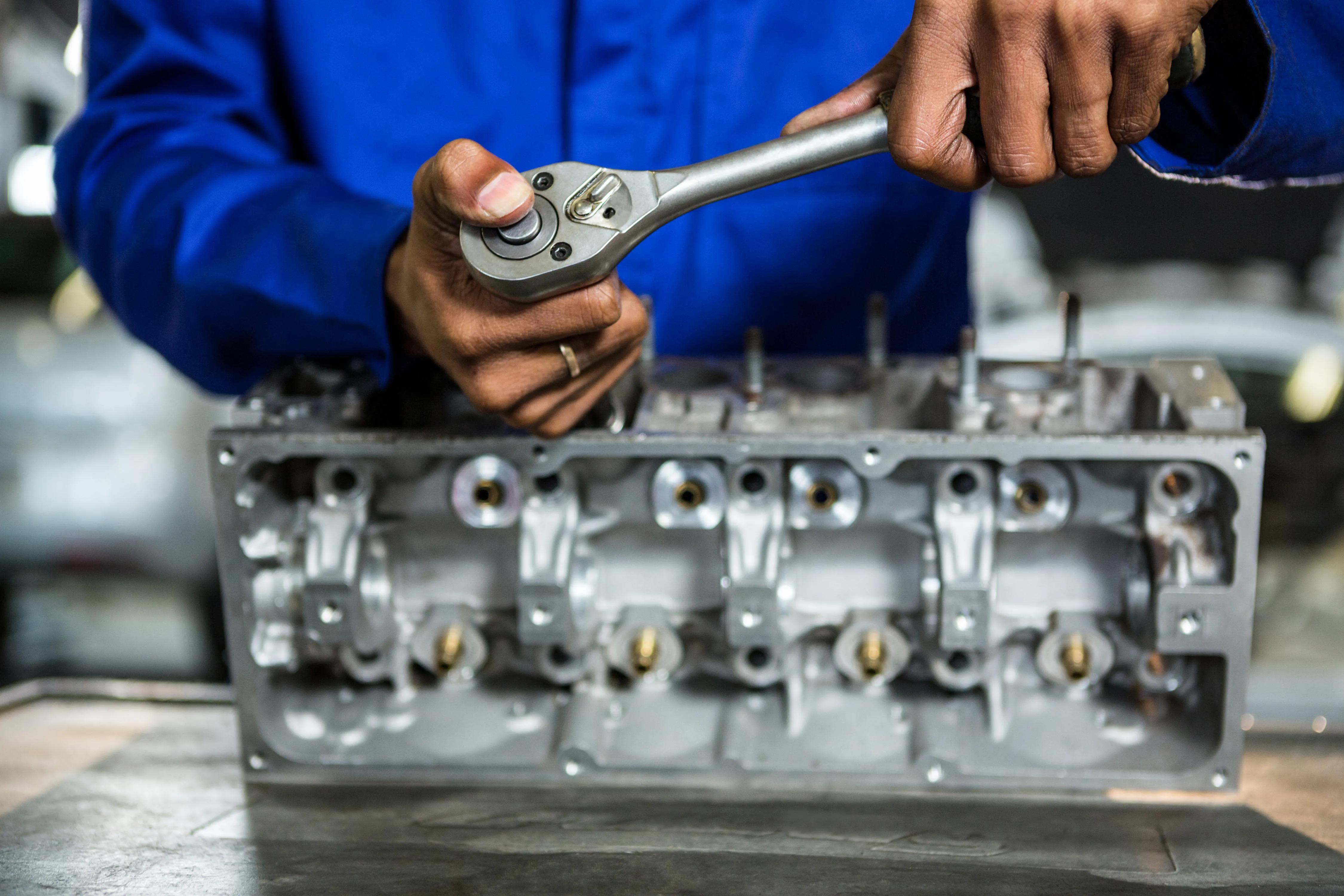

Qylvexor is a professional service station specializing in mechanical repair and component replacement for vehicles used in a wide range of operating conditions. Our work is focused on restoring correct mechanical function through structured diagnostics, precise repair actions, and careful installation of components. We approach every task with attention to detail, technical accuracy, and respect for the overall vehicle system.

Mechanical repair is not only about replacing parts. It is about understanding how components interact, identifying the source of mechanical issues, and applying solutions that support long-term functionality. This philosophy defines how we operate at Qylvexor .

Mechanical Repair Services

Qylvexor provides comprehensive mechanical repair services designed to address wear, malfunction, and structural degradation of vehicle components. All work is performed according to established technical procedures and verified repair standards.

Our mechanical repair services include:

- Engine-related mechanical repairs

- Transmission and drivetrain component servicing

- Suspension and steering system repair

- Brake system mechanical servicing

- Cooling system mechanical correction

- Exhaust and structural component repair

Each repair task begins with a technical assessment to determine the cause of the issue and define the appropriate repair strategy.

Component Replacement

Component replacement is carried out when repair is not technically appropriate or when part condition no longer meets operational requirements. Qylvexor handles component replacement with careful preparation and verification.

Component replacement services include:

- Removal of worn or damaged components

- Installation of compatible replacement parts

- Alignment and mechanical adjustment

- Functional testing after installation

- Verification of system interaction

Replacement is performed as part of a structured process to ensure correct integration within the vehicle system.

Our Repair Process

We follow a clearly defined workflow to ensure consistency and accuracy throughout every mechanical repair or replacement task.

1. Initial Inspection

The vehicle is inspected to identify mechanical irregularities and assess component condition.

2. Technical Evaluation

Mechanical systems are evaluated to determine repair feasibility or the need for replacement.

3. Repair or Replacement Planning

A structured plan is created outlining required actions and technical steps.

4. Execution

Repair or replacement is performed using proper tools and verified methods.

5. Final Verification

All repaired or replaced components are tested to confirm correct operation.

6. Documentation

Completed work is recorded for reference and future service planning.

Our Approach

Qylvexor applies a disciplined and practical approach to mechanical repair and component replacement.

Our core principles include:

- Accuracy

Mechanical work is performed with precise measurements and correct assembly. - Consistency

Standardized procedures ensure uniform service quality. - Clarity

Clients receive clear explanations of work performed and system condition. - Responsibility

Every component is treated as part of a larger mechanical system.

This approach ensures repairs are reliable, understandable, and technically sound.

Individual Repair Solutions

Mechanical needs vary depending on vehicle usage, operating environment, and service history. Qylvexor offers individual repair solutions adapted to these factors.

Individual solutions may include:

- Repair planning for high-usage vehicles

- Mechanical servicing for seasonal operation

- Structural repair for aging components

- Long-term mechanical service strategies for fleets

By tailoring repair actions to actual conditions, we support consistent vehicle operation and mechanical stability.

What You Receive When Working With Us

Clients who choose Qylvexor for mechanical repair and component replacement receive a structured and professional service experience.

You receive:

- Thorough mechanical assessment

- Clearly defined repair or replacement actions

- Methodical technical execution

- Verified post-repair functionality

- Detailed service documentation

- Practical guidance for future maintenance

Our focus is on providing clarity and reliability throughout the repair process.

Service Standards and Quality Control

Qylvexor maintains internal service standards to support accuracy and accountability.

These standards include:

- Controlled handling of mechanical components

- Verification of assembly and alignment

- Final mechanical inspection before service completion

- Accurate record-keeping of performed work

This framework ensures consistent quality across all mechanical repair services.

Ongoing Technical Development

Mechanical systems evolve, and repair practices must adapt accordingly. Qylvexor continuously reviews procedures, updates technical knowledge, and refines workflows to remain aligned with current mechanical standards and vehicle design principles.

Conclusion

Qylvexor provides mechanical repair and component replacement services built on structure, precision, and responsible execution. Through careful evaluation, disciplined repair processes, and clear communication, we help restore mechanical integrity and support dependable vehicle operation.

Our service station functions as a technical partner, delivering mechanical solutions that are grounded in professional standards and long-term usability.